Ms. Cherry

Leave a message

Ms. Cherry

Leave a message

May 12, 2018 BY TRIMS CO.,LIMITED Zippers Knowledge

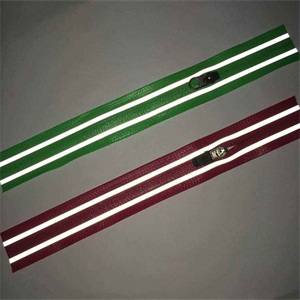

Safety is a matter of great concern to any industry, and zipper manufacturing is no exception. When designing a zipper, the safety of the wearer is our first consideration. Therefore, in addition to Brass Zipper, Waterproof Nylon Zipper, Large Plastic Zipper, Rhinestone Zipper, Invisible Nylon Zipper and other conventional zippers, our R & D team has developed a series of reflective coil zippers to improve the visibility of the wearer under different light conditions To ensure the safety of the wearer.

The prominent feature of the reflective coil zipper is that it can be clearly seen by the wearer under various lighting conditions during the day or under car lights at night. They protect the wearer from danger, thereby achieving practical and decorative purposes. Reflective coil zipper is suitable for applications that need decorative purposes, such as pockets, placket, etc. It is highly recommended for children's and sportswear.

Simply put, reflective coil zippers refer to those coil zippers whose tapes on both sides are attached with a layer of reflective strip with glass bead through heat pressing. The side with reflective strip features darker color that ensures its color fastness.

The reflective coil zipper has the following precautions in the production and use process:

1 .These zippers should be paired up with spray painted or electrophoresis sliders. Electroplated sliders are not appropriate for this type of zipper as their inner cavity is comparatively stiff and rough, whose mechanical wear-and-tear against the reflective film can cause the latter to break or fall off.

2 .Halogen dry cleaning agents can cause the reflective strip to peel off. A washing test should be carried out to double check the effect. Garment manufacturers should also speculate the washing requirements on the care labels to ensure that the end-users wash the items in a proper way.

Avoid direct contact between the zipper teeth and the cleaning agents such as laundry detergents, DJW, etc. in the manufacturing process, which can easily cause the reflective film on the teeth surface to peel off.

Avoid spraying the chemical agents that are used to get rid of dirt, rust and oil stain during the manufacturing process of the garments, luggage and bags onto the Metal Accessories and reflective strip directly. This can protect the metal parts against discoloration resulting from oxidation and keep the reflective strip from falling off due to decomposition.

3 .Keep the ironing temperate below 100℃ to protect the reflective strip from getting wrinkled.

Avoid direct contact with the reflective strip.

4 . Avoid packaging the products immediately after ironing. Allow them to dry naturally.

The plastic bags used for packaging should be kept breathable so as to protect the metal parts against oxidation that can lead to discoloration, and keep the zipper teeth from coming off due to corrosion.

5 . Avoid direct exposure to strong sunlight for a long time.

Avoid damp and corrosive (alkaline/acid) environment.

Previous: How to choose the right button

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.